The compressor is your AC unit’s important component. Without it, your system will not function. A compressor’s key job is to compress refrigerant and pump it throughout the system to remove heat and humidity from the air. Although your compressor is fairly reliable most of the time and has a lifespan of 10 to 15 years, there are times when a compressor will fail. Most often, the underlying cause is totally preventable.

When the air conditioner compressor fails, it is often due to a stress on the system. Replacing the compressor without addressing the underlying cause is setting the new unit up for failure as well. Oftentimes, the future problems that will lead to compressor failure can be detected by a simple maintenance visit by an air conditioner repair technician.

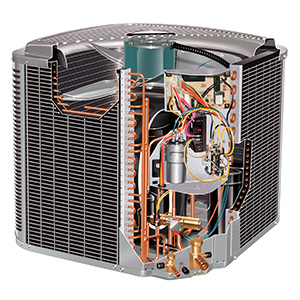

Where is the Compressor?

The compressor can be found in the outdoor air conditioning unit, at the rear or on the side of your house. The outdoor unit connects to the indoor part of your air conditioning system through a copper refrigerant tube. Once connected, these two parts work together to absorb hot air from inside your home and transform it into cool air.

What is the Function of the Compressor?

The air conditioner pulls heat out of the air in your home, cools it over a set of cold pipes (an evaporator coil), and releases the cool air into your home. The compressor is responsible for moving the refrigerant between the evaporator and condenser coils, ensuring that the refrigerant changes to gas or liquid as needed. You can think of the compressor as the heart of the air conditioning system and the refrigerant as the blood. To this end, the compressor pumps the refrigerant through the system to keep it alive and running properly.

Symptoms of AC Compressor Failure

- The system is blowing warm air

- The compressor does not turn on at all

- The outside unit shakes when it starts up

- The system keeps tripping the circuit breaker

- The outside condensing unit is making strange noises

Avoidable Causes of AC Compressor Failure

1. Dirty Compressor Coils

Your air conditioner is exposed to pollutants, dust and debris from both indoors and out. As a result, grime and residue build-up on the condenser coils of the unit. Left untreated, the buildup of dirt, dust, and even mineral deposits on your condenser coils can choke the system so that heat is not effectively expelled. Having your unit cleaned at the change of the seasons should significantly reduce the impact of the environment.

2. Blocked Suction Lines

Blockage in the refrigerant lines will cause any system to lose cooling efficiency. The increase in pressure and temperature will grow worse over time – this is often slow enough to go unnoticed, but it can be very rapid. Eventually, overheating causes compressor failure.

3. Too Little Refrigerant

With hoses and materials that could break down over time, leaks can develop in your unit, causing the refrigerant to escape. If your system’s refrigerant lines develop holes or cracks, the air conditioner leaks refrigerant. After a while, the level becomes so low that the compressor has to work harder to pump enough refrigerant through the system to cool your space. The strain can eventually cause the compressor to break down.

4. Too Much Refrigerant

Having too much refrigerant in your unit can be just as detrimental as having too little. If a less-than-qualified person works on your air conditioner and inadvertently adds too much refrigerant, or even the wrong type of refrigerant, it can be a deadly mistake for the compressor. Be sure to have a professional charge your system with the correct product for your model.

5. Incorrect Suction Line Size

Experienced compressor technicians should perform all maintenance when it comes to sensitive interior parts. A line that is too small or too large can make the compressor unit fail prematurely.

6. Electrical Issues

Several parts of the air conditioning unit can become damaged in the event of electrical failure or burnout. Wiring, fuses, and contacts should be examined by compressor experts. Electrical burnout within a compressor can cause acid buildup that damages multiple components. Routine maintenance can prevent full system failure should signs of electrical issues appear. If you have a failed compressor, make sure the technician tests for the presence of these acids. If he finds them, an electrical burnout has caused damage throughout the system that is probably not worth fixing.

7. Contaminants (Airborne and Otherwise)

Compressor housing provides some protection against contaminants, but it is always a good idea to maintain high sanitation standards in your space. Moisture, dirt, debris, leaves, soot, acids, and even bird and pest droppings can wreak havoc on your compressor. Follow all OEM instructions on periodically cleaning compressor exteriors.

8. Inadequate System Lubrication

Lubricant levels affect the performance of virtually all parts of your system. Think of the lubricant in the compressor unit in much the same way lubricant works in a car engine. Your compressor unit needs to stay lubricated for it to function efficiently, which is why you need to have it checked for low lubrication levels. If there is not enough lubricant, the system can suffer failure after some time.

Give Us a Call

One of your worst fears is having to replace the heater or air conditioner in your home. But with due diligence, you can prevent a premature replacement and the associated costs.

If your system needs repair or inspection, call Aire-Tech at 951-926-1002. You can also visit our Contact page and complete the contact form.